The Ultimate Guide to Understanding the Importance and Benefits of Strip Brushes

/0 Comments/in Blog /by BolexbrushUnleashing the Power of Strip Brushes: The Secret Weapon for Cleaner, Safer Surfaces

/0 Comments/in Blog /by BolexbrushWhen it comes to maintaining cleanliness and safety in various industries, strip brushes are often the unsung heroes. These unassuming tools have been serving a multitude of purposes for decades, proving themselves as the secret weapon for achieving cleaner, safer surfaces. In this blog post, we will explore the diverse applications of strip brushes and highlight their remarkable capabilities.

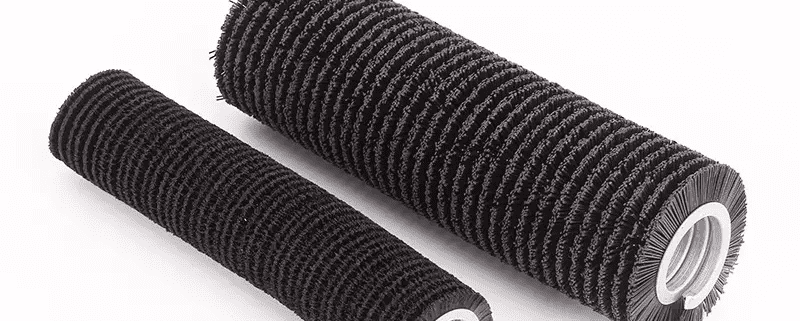

A Versatile Cleaning Solution

Strip brushes are renowned for their versatility in tackling various cleaning challenges. Whether removing debris, dust, or tough grime, strip brushes excel in various industries. These brushes are vital in maintaining hygienic and safe environments, from manufacturing plants and food processing facilities to car washes and commercial kitchens.

Perfect for Industrial Applications

In industrial settings, strip brushes are indispensable for maintaining equipment efficiency and ensuring workplace safety. They are commonly used to prevent the accumulation of dirt, metal chips, and other particles on conveyor belts, thereby extending their lifespan and minimizing downtime. Strip brushes seal gaps, preventing dust and contaminants from infiltrating machinery and reducing noise and vibration.

Effective in the Food Industry

Maintaining cleanliness in the food industry is of paramount importance. Strip brushes have proven to be invaluable tools in this sector. They clean conveyor belts, removing food particles and ensuring compliance with stringent hygiene standards. Additionally, strip brushes play a crucial role in fruit and vegetable processing, effectively removing dirt, wax, and pesticide residues from produce.

Automotive Applications

Strip brushes are widely used in the automotive industry for cleaning and sealing. Car washes rely on strip brushes to remove dirt and grime from vehicle surfaces, providing a thorough and efficient cleaning process. In manufacturing plants, strip brushes are crucial in sealing doors and windows, preventing dust, drafts, and noise from entering the vehicle’s interior.

Brushing Up in Printing and Packaging

Strip brushes are essential for maintaining high-quality production standards in the printing and packaging industry. They are used to clean printing plates, removing excess ink and debris, resulting in sharp and precise prints. Strip brushes also play a key role in preventing paper jams and ensuring the smooth operation of conveyor systems, reducing downtime and increasing productivity.

The Perfect Fit for Escalators and Elevators

Strip brushes find their niche in the transportation sector as well. They are employed in escalators and elevators to maintain cleanliness and enhance passenger safety. By effectively removing dirt, dust, and debris from moving components, strip brushes minimize wear and tear, extending the lifespan of these vital transportation systems.

Customization for Unique Applications

One of the remarkable aspects of strip brushes is their versatility in customization. They can be tailored to meet requirements, including brush length, density, and material. This flexibility ensures that strip brushes are optimized for various applications, guaranteeing maximum effectiveness and efficiency.

In conclusion, strip brushes are the unsung heroes of cleanliness and safety in various industries. Their versatility, adaptability, and effectiveness make them a secret weapon for achieving cleaner, safer surfaces. From industrial applications to the food industry, the automotive sector, and beyond, strip brushes are vital in maintaining hygienic environments, increasing efficiency, and reducing maintenance costs. Whether you need to clean, seal, or protect, strip brushes are the go-to solution for businesses seeking to enhance their operational performance and ensure a safe working environment. So, unleash the power of strip brushes and experience the remarkable difference they can make in your industry!

Introduction of strip brush ?

/0 Comments/in Blog, News /by BolexbrushA strip brush, also known as a weather stripping brush, is a type of brush that is used to seal gaps and cracks in doors, windows, and other similar openings. It helps prevent air and moisture from entering the space, thereby improving energy efficiency and reducing heating and cooling costs. Strip brushes are typically made of a flexible, durable material such as plastic, nylon, or steel and are available in various sizes and shapes to fit different types of openings.

Strip brushes are an ideal solution for anyone looking to improve the energy efficiency of their home or office. They are easy to install, maintenance-free, and offer long-lasting performance. In addition, they can be used in a wide range of applications, from residential homes to commercial buildings and industrial facilities.

If you’re interested in purchasing strip brushes for your home or business, there are a few things to keep in mind. Firstly, make sure to measure the size of the gap or crack that you want to seal so that you can purchase the appropriate size of brush. Secondly, consider the type of material that you prefer, as different material s offer different levels of durability and performance. Finally, choose a reputable supplier with a good track record for supplying high-quality strip brushes.

s offer different levels of durability and performance. Finally, choose a reputable supplier with a good track record for supplying high-quality strip brushes.

Overall, strip brushes are an effective and cost-efficient solution for anyone looking to improve the energy efficiency of their home or office. Whether you’re a homeowner, contractor, or building manager, strip brushes are a must-have for anyone looking to save energy and reduce costs.

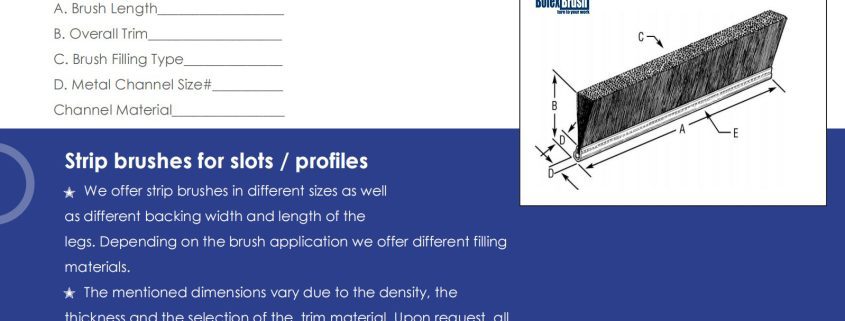

How to choose a suitable brush? You should know about the brush filling materials first!

/0 Comments/in Blog, File, News /by BolexbrushThe most important part of the brush is the filament. Below is a partial list of what is available for the fill materials..

Filling material falls into basically three types:

1.Synthetic = Man made plastics

2.Natural = Hair, bristle or vegetable fiber

3.Wire = Strands of metallic filament

Synthetic Brush Materials

- Nylon: The most widely used and versatile fiber used today. Nylon is highly durable because of its high abrasion resistance and bend recovery. Nylon bristles discourage bacterial growth and resist most acids. It is non-shedding, and is excellent for cleaning and scrubbing applications with its strong abrasion resistance properties. It does not scratch most surfaces.

- Polypropylene: it is a popular synthetic filament used in a wide variety of applications. Like nylon, it is mainly manufactured in the CHINA . Its low specific gravity offers a low cost high performance fiber for wet or dry applications. Polypropylene has excellent stiffness when wet, is non-brittle, is inert to most solvents, oils, acids and chemicals, and is fungus resistant. Polypropylene will take a set much quicker than nylon will (not bend back to its original shape). Polypropylene has excellent stiffness when wet and is inert to most solvents, oils, acids or chemicals and is fungus resistance.

- Polyester : Used in some applications where it is exposed to sunlight or solvents. It has better abrasion resistance than polypropylene, but not as goods as nylon. It also has excellent bend recovery, excellent solvent resistance and excellent oxidation resistance at high temperature. The properties of polyester do not change significantly between wet and dry applications because it does not absorb much water.

Natural Brush Materials

- Horse hair : The hair from a horse’s mane or tail has a long tradition of usefulness. Horsehair is valued according to stiffness, length and color. It works well for sweeping polished surfaces, dusting, flux removal and general cleanup and is non-conductive.

- Bristle : The hair that comes from a member of the suidae family: hog, swine, pig sow or boar is called bristle. Bristle comes from along the back near the spine of these animals. Bristle is resilient and is the stiffest natural material available. A hog bristle brush will provide the best possible cleaning. It works well when dealing with tough sticky materials or viscous fluids. It is non conductive but will generate less static than synthetic materials.

Wire Brush Materials

- Stainless Steel : Is available in 3 types, #302, #304 and #316. These supply tensile strength, fatigue strength and high corrosion resistance. Stainless steel is used to prevent harmful ferrous deposits on brushed parts and is quite aggressive in larger diameters.

- Steel Wire : Carbon steel wire is available in high carbon and low carbon depending on your application. Carbon steel wire is used where stainless steel wire or higher cost is not needed. Steel wire can be very aggressive.

- Brass wire . This wire is 70% copper and 30% zinc. we uses only the highest quality brass, which is highly conductive and corrosive resistant and non-sparking. This wire is used in the manufacture of all brass brushes.

Latest Products

Latest News

Product Category

Contact Us

Phone:008618613144964

Email: [email protected]

ADD:NO.1 GONGYE ROAD ,CONGHUA ECONOMIC DEVELOPMENT ZONE,TAIPING TOWN,CONGHUA DISTRICT,GUANGZHOU ,CHINA

BOLEXBRUSH

BOLEXBRUSH