The Best Strip Brushes and it’s Amazing Benefits

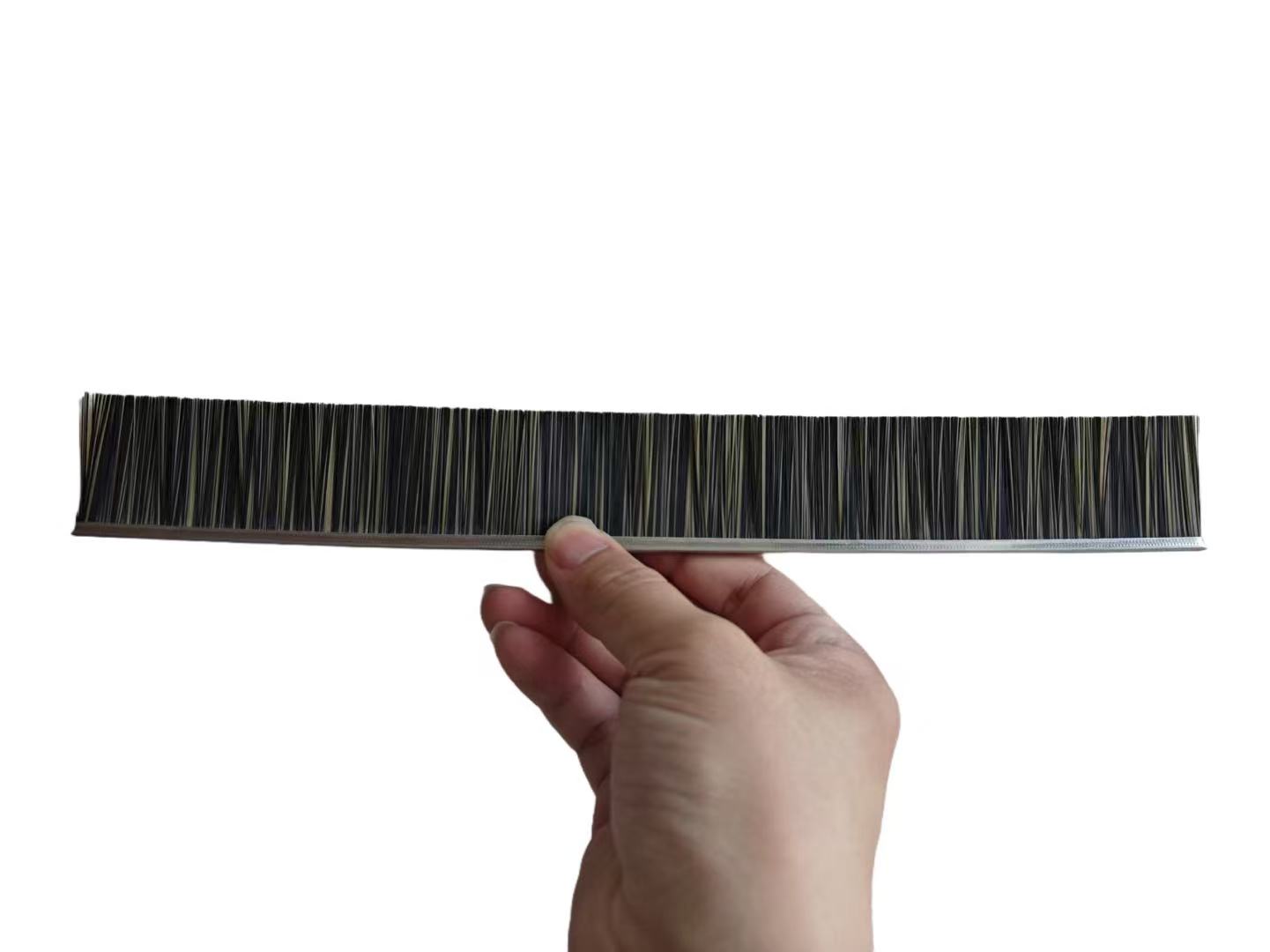

Strip brushes are extremely adaptable products and they are widely applied in the industrial, commercial and maintenance processes. One of the biggest applications of strip brushes is the use of these for taping. Prevent dust, debris, air, light and noise are prevented using strip brushes mounted around machine openings such as doors or enclosure of conveyor systems. This sealing business assists in developing a cleaner work environment, high efficiency energy savings and controls of sensitive machinery. Are you someone who wants to gather more facts about the strip brushes? If Yes. This is the best place where people can gather more facts about the strip brushes.

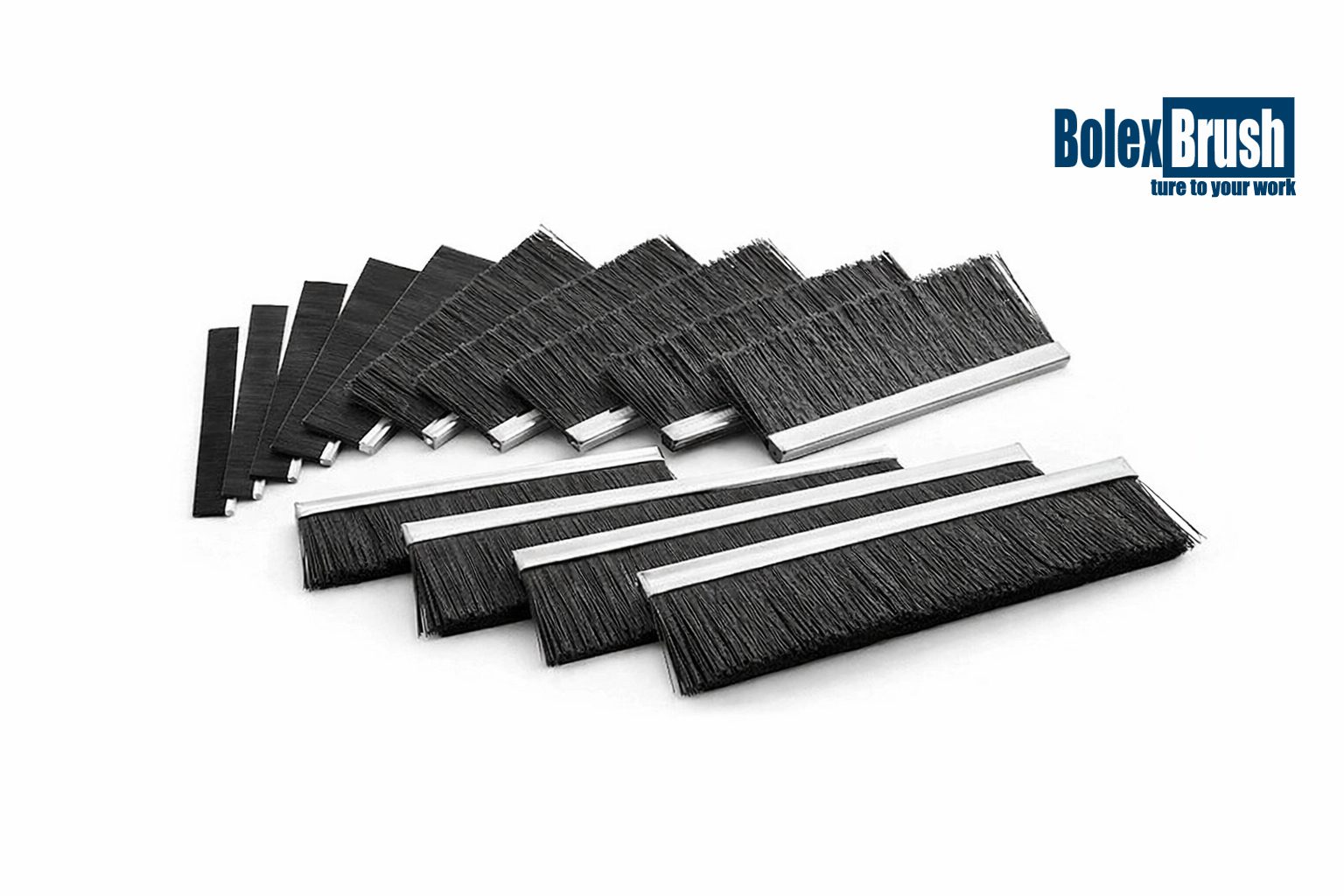

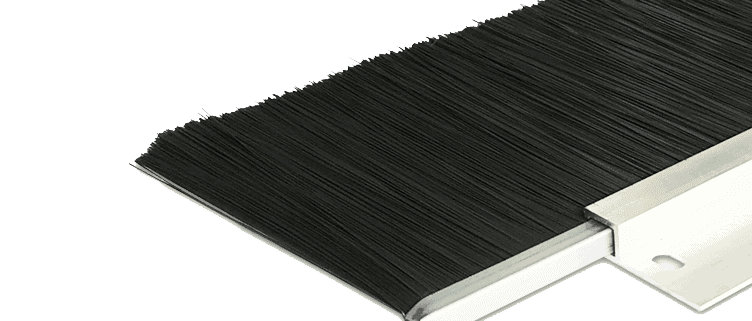

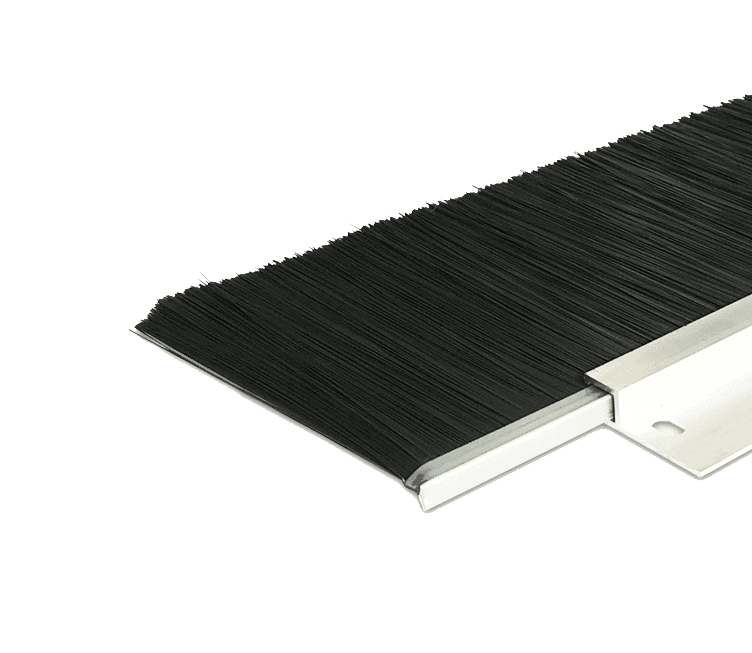

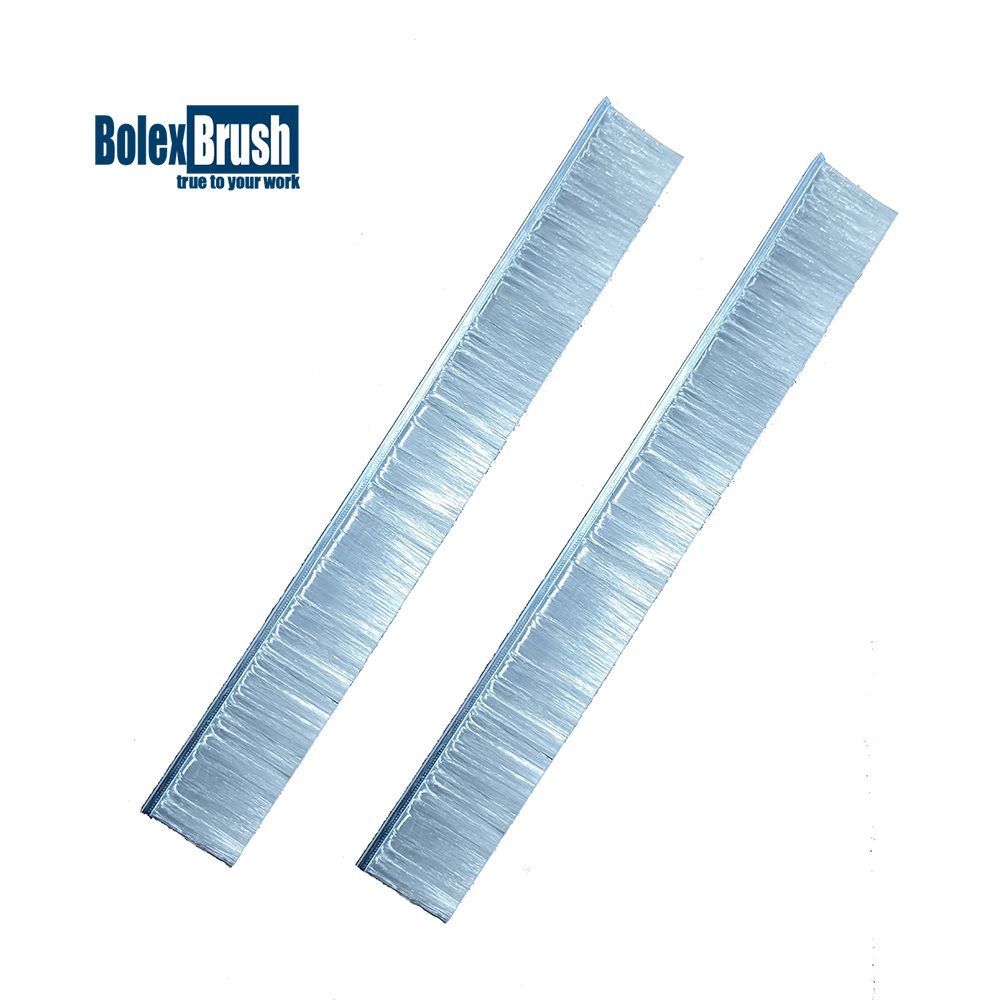

The strip brushes

The second key benefit of strip brushes is that it enables them to guide and protect materials. The strip brushes are implemented on conveyor machines and other handling machines to make sure that the products are aligned, reduce vibration and prevent scratches or damage to the products that are moving. It is a protection disposition that ensures maintenance of quality of the products and saves time and resources that would have been used in repairing damages caused during handling.

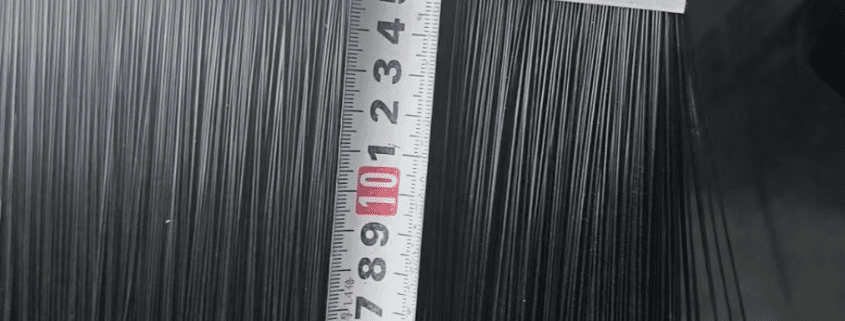

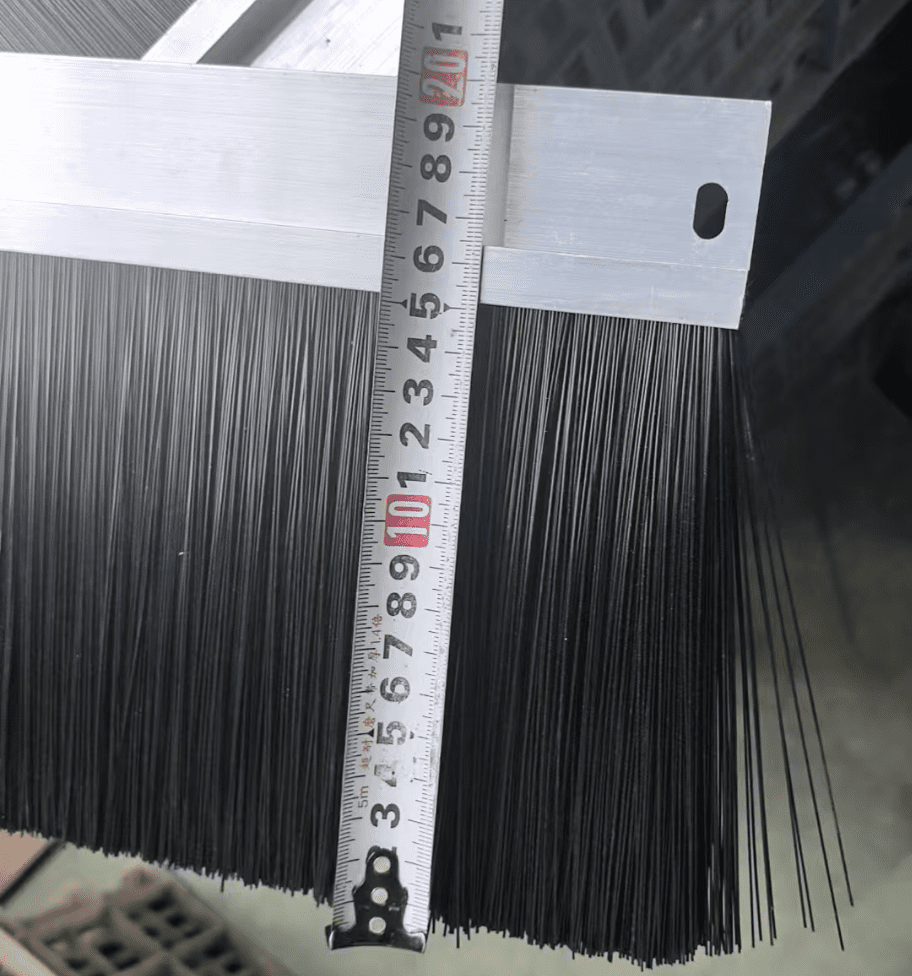

The major advantage of strip brushes is customization. They can be constructed as per the length and density of the bristles and made of various materials such as nylon, polypropylene, natural materials and even wire.

Durability and convenient installation is also good added value to them. High quality strip brushes are the product that is produced keeping in view the goal of using it in the rough environment with minimum care.

The strip brushes are convenient, cost-effective and reliable in huge number of applications. Their sealant, cleaning, guiding and protective characteristics assist in making them to be a very crucial tool of industrial and commercial working in the present society. Go ahead! And claim the top benefits of the best strip brushes.